THE BASICS OF CUTTING AND POLISHING A ROUGH DIAMOND

The rough diamond

goes through many processes, working to achieve the desired plan for the

finished diamond. Below you will see a simplified list of the actions taken

throughout this process. Note that depending on the characteristics of the

rough diamond some of these actions could be repeated or take place in a

different order. 1. Pre-Process

Sorting

2. Planning and Marking 3a. Cleaving

3b. Laser Sawing 3c. Sawing 4. Bruting 5. Blocking 6. Brillianteering 7. Final Quality Check and Re-polishing At each stage of the process above, there is a quality assurance (QA)

check to assess the stone against the plan. The stone may be re-planned if

necessary, to allow the team to deal with unexpected challenges or to move to a

more commercially viable option. This might be as a result of changing market

conditions or a change in potential yield.

PROCESSES 1 - PRE-PROCESS SORTING Before cutting and polishing begins, the rough

diamonds may need to be sorted into categories to help with workflow and

prioritise certain rough diamonds to complete orders. The teams may look at: and assess the need for window polishing, where one

or more very small facets are polished onto the rough to allow the planner

to make a more accurate decision around clarity features. 2 - PLANNING AND MARKING Planning is the process of deciding how to cut and

polish a diamond to maximise its value. In today’s manufacturing environment,

planners use a combination of their skills and technology. The planning stage includes: · Creating

a 3D surface model of the rough diamond (not used for small diamonds due to

cost) · Plotting

clarity features · Planning

the cutting and polishing to maximise yield · Pre

process sorting Once the plan has been chosen, if the stone needs

to be cut it will be marked by pen or automated laser marking to show the

cleaver/sawyer where the cut should be made. It is during this planning stage

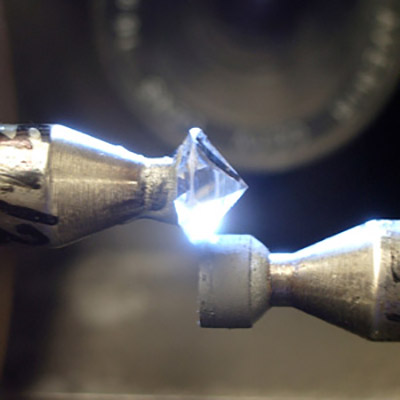

when the decision on whether to saw, cleave or polish the diamond will be made. 3A – CLEAVING Many diamonds require dividing into more than one

part to get the best overall yield and/or clarity. One process used to divide a

diamond is cleaving, and is often performed on stones where the structure has

internal cracks and fractures so a better over-all clarity can be achieved with

its removal or avoidance. The cleaving process involves: Laser kerfing is highly accurate, allowing precise

control of the location, direction, width and depth of the kerf and even the

removal of small pieces of diamond. Diamond cleavers need an extensive

knowledge of the structure and qualities of diamonds. Cleaving

is preferable to sawing wherever possible, since it involves less wastage.

Diamond cleavers need exceptional skills and in-depth knowledge of the

structure and properties of diamonds. They must understand the inherent

potential of every individual stone. Their familiarity with the different types

of rough stones enables them to maximize the potential of every gem, especially

those with a complex or heavily included structure. 3B – LASER SAWING ‘Laser’ stands for ‘light amplification by the

stimulated emissions of radiation’. It has revolutionised the diamond cutting industry,

offering savings in time and money. It enables the cutting of material that

would have been unworkable previously, and can greatly reduce the risk of

damage. It also allows an almost limitless assortment of fancy shapes, as you

are not restricted by the crystal structure of the diamond. The reason you are

not restricted is because the laser burns the crystal structure. 3C – SAWING Blade sawing can only be carried out on a diamond

in certain directions which are different from the cleavage directions. Before

any sawing takes place the stone is marked with a line where the blade will

divide the stone. The sawing machine consists of a metal frame that

has a weighted arm mounted from the back. The diamond is held in a clamping arm

that is mounted on the arm above the saw blade. At the rear of the arm there is

a counter weight which controls the lowering of the diamond onto the saw blade

allowing the sawing action takes place. The sawyer can be responsible for

multiple machines and is in charge of changing pressure of the weight and

applying sawing powder to the blades. It takes approximately an hour to an hour

and half to saw 1ct. of diamond. 4 - BRUTING Bruting is the process of rounding or shaping the

diamond by rotating it against another diamond. The cutter works on sawn,

cleaved or whole stones. At this stage the stone receives its precise shape -

the exact diameter and location of the girdle and the locations of the table

and the culet. 5 - BLOCKING Blocking is the process of creating the basic shape

of the diamond. It involves the polishing of eight facets on the crown, and

eight facets on the pavilion of the diamond. Blocking can be done on the polishing wheel setup. 6 - BRILLIANTEERING This is the final stage in transforming the

diamond. This is for a Round Brilliant Cut but the same

method is deployed for fancy shapes – albeit to different shape plans. 7 - FINAL QUALITY CHECK AND ANY

RE-POLISHING As the transformation comes to an end, the final

stage is a quality control check to look at yield as well as: The quality checking process involves the use of

microscopes as well as loupes, and will ensure that the best diamond is finally

released from the rough crystal.

Once the stone has been laser sawn, it looks blackish and opaque. Cleaning

procedures return it to its original appearance.

During blade sawing, weight loss of approximately 2% is expected.